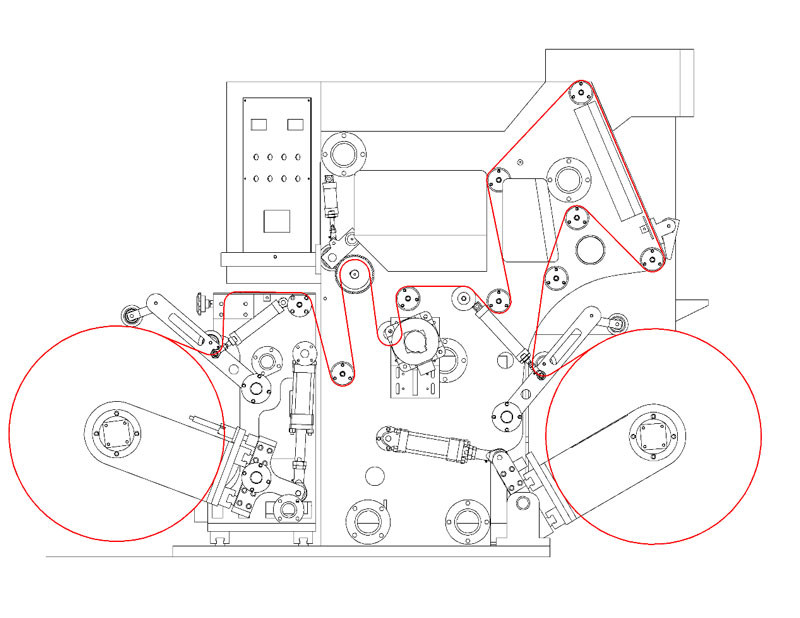

1.Main motor inverter introduced by 1 pcs of BSD vector inverter.

2.Main motor introduced by 1 pcs BSD vector motor.

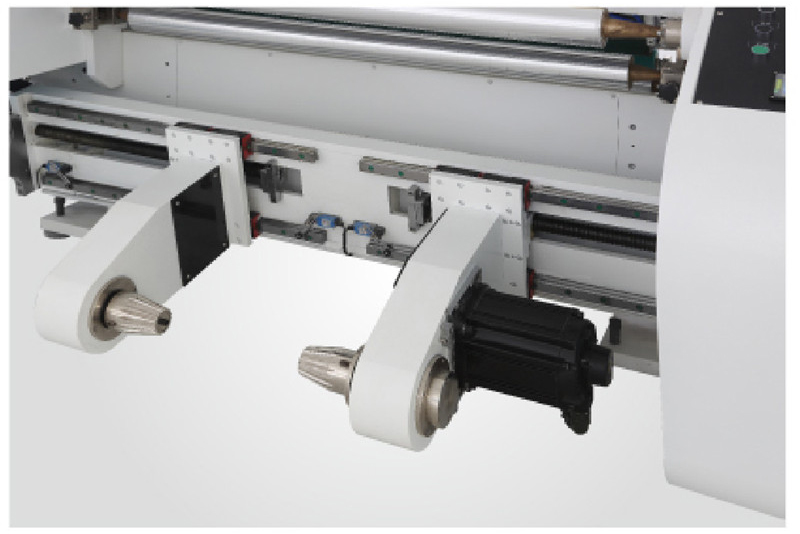

3.Rewind motor inverter introduced by 2 pcs of BSD vector inverters.

4.Rewind motor inverter introduced by 2 pcs of BSD vector motors.

5.LPC adopts analog control. Driving by servo motor through CCD.

6.It adopt imported PLC to achieve accurate and stable control, real-color touch screen display to enable simple and beautiful images. Interactive parameter setting the environment, eliminating the complicated configuration can start the job: The user pre-start only need to input the material thickness, width, density, diameter and speed parameters, and next process will be automatically done by a computer calculation

It is suitable for various kinds of plastic film and laminated film, etc like BOPP,PET,PVC,Aluminum foil etc.

Q: What is the MOQ ?

A: 1 set of each machine

Q: Can you provide a corresponding slitting solution for us ?

A: Yes, please advise the plastic material,max web width and ideal unwind & rewind diameter that you need

Q: How can we make quality acceptance?

A: We’re gonna have zoom video to show whole test trial process

Q: Can we have additional slip differential sleeve on rewind unit?

A: Yes, there’re different size like 20mm, 25mm, 50mm for option

Q: What is the standard packaging way by ocean?

A: Usually we would pack it in exported wooden pallet